Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Fe | Ni | Others | Hardness | Density (deposit) | Melting Range |

| Bal | 32.5 | 17.5 | 2.5 | 2.0 | 2.0 | Mn, Si | 50-63 HRC | 8.76 g/cm3 0.316 lb/in3 | 1215-1299ºC 2220-2370ºF |

| Co | Cr | W | C | Fe | Ni | Others | Hardness | Density (deposit) | Melting Range |

| Bal | 32.5 | 17.5 | 2.5 | 2.0 | 2.0 | Mn, Si | 50-63 HRC | 8.76 g/cm3 0.316 lb/in3 | 1215-1299ºC 2220-2370ºF |

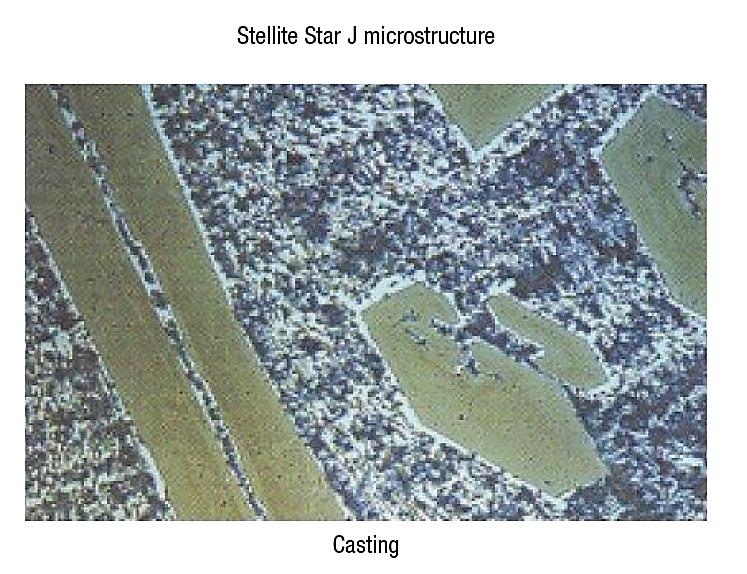

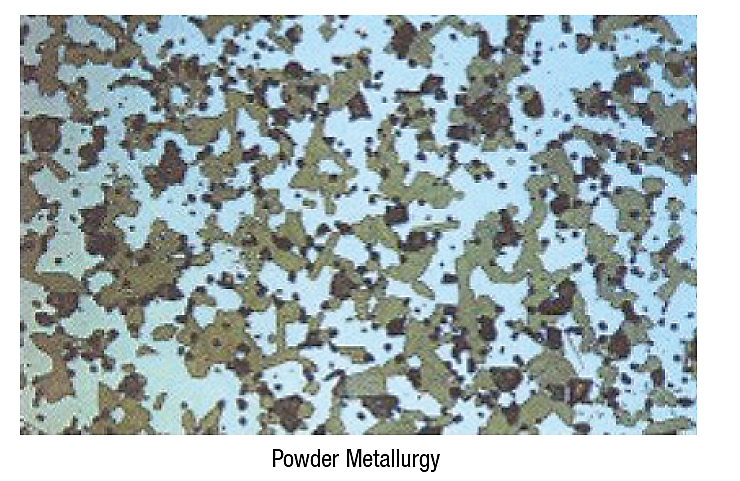

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite Star J is recommended for use in extreme conditions of wear, abrasion, and heat. The alloy is similar to Stellite 3 in carbon content but with a higher tungsten content. This results in higher hot hardness and superior strength. The tungsten also changes the morphology and type of carbides resulting in improved abrasion resistance at the expense of ductility. Wear parts such as pads, pins, balls, and certain valve components in extreme environments are common applications for Stellite Star J.

| DESIGNATION | PRODUCT FORM |

| UNS R31001 | Castings |

| UNS R301012 | Powder Metallurgy |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?