Nominal Composition (Mass %) and Physical Properties

| Fe | C | Cr | Si | Others | Hardness | Density | Melting Range |

| Base | 2.8 | 27 | 1 | Mn, V | 50-64 HRC* | 7.92 g/cm3 0.286 lb/in3 | 1255-1307ºC 2290-2385ºF |

*Higher hardness is obtained with heat treatment.

| Fe | C | Cr | Si | Others | Hardness | Density | Melting Range |

| Base | 2.8 | 27 | 1 | Mn, V | 50-64 HRC* | 7.92 g/cm3 0.286 lb/in3 | 1255-1307ºC 2290-2385ºF |

*Higher hardness is obtained with heat treatment.

Delcrome Alloys are iron-based alloys with grades ranging from 316 and 410 stainless steels to much harder, wear-resistant, white cast irons. Delcrome alloy grades can be suitable for addressing general-purpose wear applications, with the harder grades typically used where abrasive wear is the primary concern.

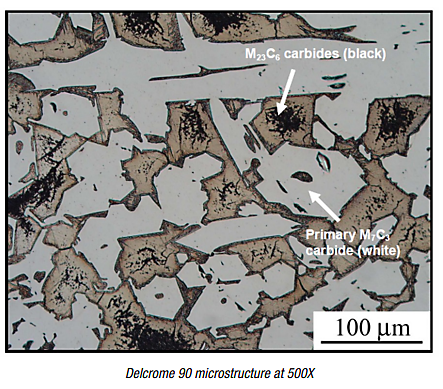

Delcrome 90 is a specialty white cast iron with exceptional properties for components that must resist abrasive wear. It is generally not suitable for corrosive applications and, due to its brittleness, should be avoided when impact and shock are factors. Carbide modifiers in this iron provide refined microstructure and improved erosion resistance. Delcrome 90 can be annealed to enable economic machining operations and subsequently hardened to develop high compressive strength and wear properties. The corrosion resistance of this alloy is generally superior to mild steel, but less than 410 stainless steel.

Delcrome 90 is often used in applications where strong abrasive wear is prevalent, such as mineral processing and mining industries. Mill liners, impellers and wear plates are a few of the common applications.

Delcrome 90 is available as finished castings, wire and powder.

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?