Premium-Quality HVOF Coating

JK 125 is a thermal spray powder developed specifically for the deposition of high-quality HVOF coatings. This HVOF powder contains mixed (W,Cr)C and WC carbides in a nickel and nickel-chrome matrix. When deposited correctly using the Jet Kote HVOF system, JK 125 coatings are equivalent to Praxair D-Gun® LW-5 coatings.

Typical Applications

JK 125 HVOF coatings have improved corrosion resistance in

some environments compared to WC/Co coatings, because of the nickel and nickel-chrome matrix. They have excellent resistance to salt, sea water and amine environments, and moderate resistance to sulfuric acid. They are not recommended for nitric or hydrochloric acid environments.

JK 125 coatings are also recommended for wear applications where oxidation resistance superior to WC/Co is required. They are used for wear resistance in oxidizing atmospheres up to 650°C (1200°F) or higher, for example on seals and bearings for process fluid pumps and on cutters for food processing. Sub-sea and process plant valves are other typical applications. As it contains no cobalt, JK 125 may also be considered for nuclear applications.

Application Example

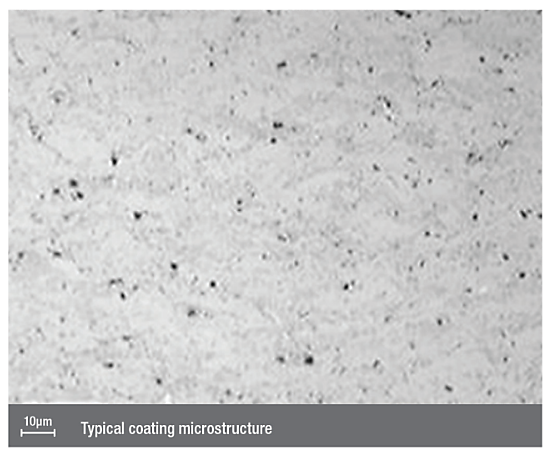

JK 125 has been deposited by Kennametal Stellite™ on InconelTM 625 nuclear pump plungers as a fully OEM-qualified substitute for Praxair D-Gun LW-5. The coating properties such as bond strength, porosity, hardness and microstructure have all been verified as equivalent to those of Praxair D-Gun LW-5 coating.

Finishing of JK 125 HVOF Coatings

JK 125 coatings are typically finished to 8–16 μ-inches by wet grinding with open friable diamond wheels. They can also be super finished to below 1 μ-inch (0.025μm) if required.