Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Si | Others | Hardness | Density | Melting Range |

| Base | 31 | 10.5 | 1.9 | 1.0 | Ni, Fe | 51-53 HRC | 8.36 g/cm3 0.302 lb/in3 | 1239-1299ºC 2263-2370ºF |

| Co | Cr | W | C | Si | Others | Hardness | Density | Melting Range |

| Base | 31 | 10.5 | 1.9 | 1.0 | Ni, Fe | 51-53 HRC | 8.36 g/cm3 0.302 lb/in3 | 1239-1299ºC 2263-2370ºF |

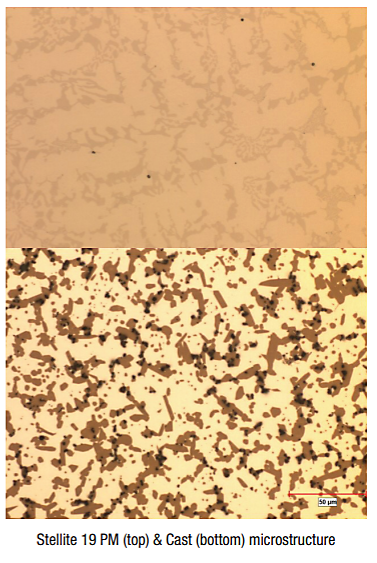

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite 19 is resistant to severe shock and has excellent red-hardness for applications such as cutting tools, machinery parts, high-temperature bearing races, nozzle discs, and burnishing rollers.

One of the outstanding properties of Stellite 19 is its ability to remain hard at red heat. This denotes a range of temperatures from 932 to 1562°F. Stellite 19 has impact resistance that is comparable to high-speed steels but has much higher red hardness. Stellite 19 can be used at higher speeds than high-speed steels. Its excellent resistance to corrosion from many common chemicals combined with its abrasion-resistant qualities makes the use of this alloy economical for machining such materials as plastics and rubber, which liberate corrosives that are used in their manufacture.

Stellite 19 is available as a casting and powder metallurgy components.

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?