Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | Ni | C | Others | Hardness | Density | Melting Range |

| Base | 28 | 20 | 5.0 | 0.9 | V, Fe, Si, Mn | 45-50 HRC | 9.02 g/cm3 0.326 lb/in3 | 1230-1300ºC 2246-2372ºF |

| Co | Cr | W | Ni | C | Others | Hardness | Density | Melting Range |

| Base | 28 | 20 | 5.0 | 0.9 | V, Fe, Si, Mn | 45-50 HRC | 9.02 g/cm3 0.326 lb/in3 | 1230-1300ºC 2246-2372ºF |

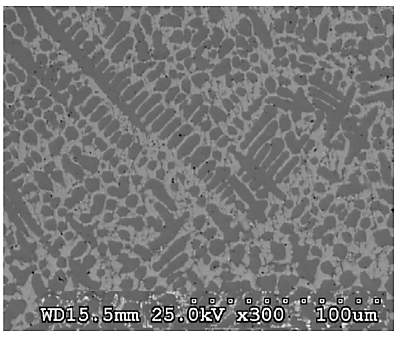

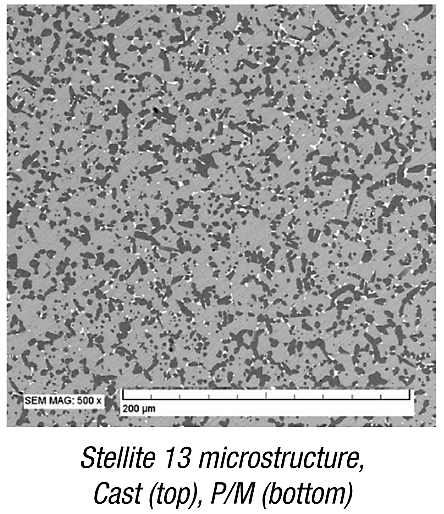

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite 13 was designed for good general resistance to wear, erosion, and oxidation. Stellite 13 is used in a range of applications where a strong balance of wear and corrosion properties are required while also retaining good ductility and machinability. It has improved corrosion resistance relative to Stellite grades such as Stellite 6, Stellite 12 and Stellite 3.

Stellite 13 is available as a casting, powder metallurgy components, and solid welding wire.

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?