Stellite 21

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite 21 (previously known as Stellite 8) was developed

in the mid-1930s as a corrosion-resistant CoCr alloy, and rapidly found application as a biocompatible hip implant and denture alloy. Many of the alloys currently used in medical applications are variants of the original Stellite 21 composition. It was also one of the first heat-resistant alloys trialed for use in jet engines.

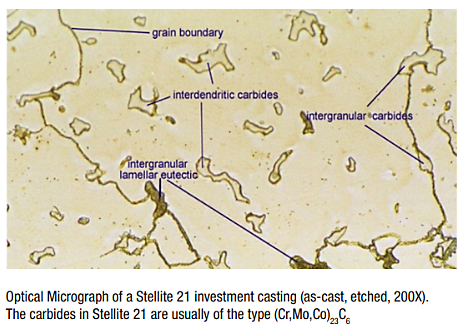

Stellite 21 consists of a CoCrMo alloy matrix containing dispersed hard carbides which strengthen the alloy and increase its hardness but also decrease the ductility. The type, shape, size and distribution of the carbides is strongly influenced

by the processing history of the alloy, and for this reason the mechanical properties of Stellite 21 are very dependent upon the manufacturing route and any subsequent heat treatments.

Due to the low volume fraction of carbides, the Co-based alloy matrix dominates the wear and corrosion properties. Stellite 21 has excellent cavitation, galling, and metal-to-metal sliding wear resistance, but is not recommended for severe hard particle abrasion. The surface can work harden considerably during wear or even during machining, and the use of correct machining tools and techniques is important to achieve optimal results.

Stellite 21 has excellent resistance to thermal and mechanical shock. Optimum high-temperature strength is obtained by solution heat treatments at 1200–1240C (2190–2265F) followed by quenching and aging in the temperature range 700–1150C (1290–2100F).

Stellite 21 can be cast, powder metallurgically processed, or applied as a weld hardfacing. It is recommended for applications involving cavitation, erosion, corrosion and/or high temperatures, such as valve trim for petrochemical and power generation. Due to its good impact resistance, it has been widely used in the building up of forging or hot stamping dies. The oxyacetylene weld deposition method is not recommended for this alloy.