Stellite 700 Alloys

Stellite 700 alloys raise the standards for wear and corrosion-resistant alloys. They have the unusual combination of excellent wear resistance and exceptional corrosion resistance in environments that are either reducing or complex.

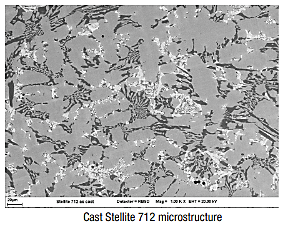

Stellite 700 alloys are cobalt based with chromium and molybdenum as major alloying elements. The unique combination of wear and corrosion properties result from the high-volume fraction of carbide particles and high degree of solid-solution strengthening from the addition of molybdenum. The STELLITE 700 alloys have been particularly successful in petrochemical and refinery applications, such as delayed coker-fired heater return bends, catalyst withdrawl lines and conveyance, as well as FCC feed and regenerator air and grid nozzles. Valve seats, slides, and general flow-control applications where corrosion and wear are key considerations are also good candidates. The 700 series alloys have broad application wherever there is a combination of high wear with corrosion.

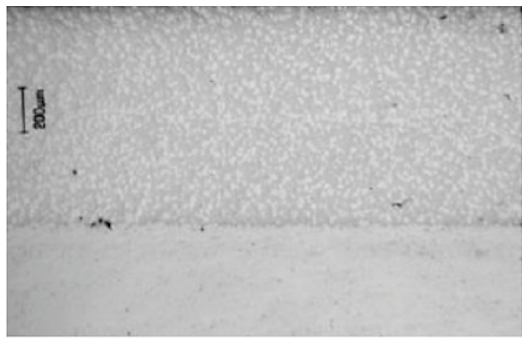

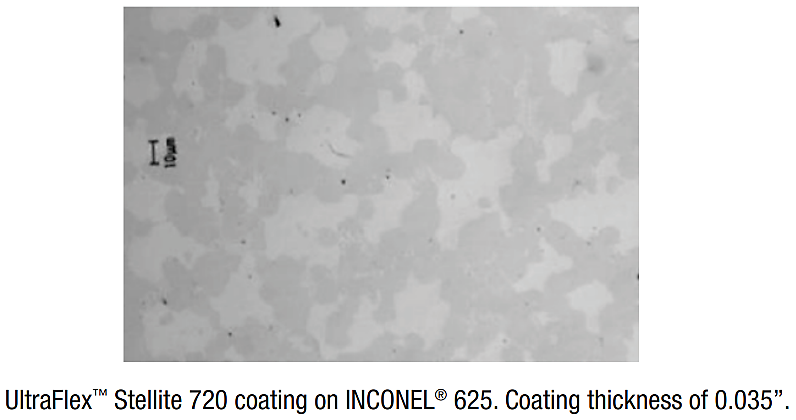

Stellite 720 coatings are available with the proprietary UltraFlex™ process, which is able to deliver this extremely wear- and corrosion-resistant alloy to the surfaces of complex and non-line-of-sight components. Stellite 720 is also available as additively manufactured components.

Stellite 700 alloys are based on the traditional Stellite grades 6, 12, 3 and 20, but tungsten has been replaced with molybdenum. This allows them to retain their hardness and wear properties while substantially improving corrosion resistance in reducing environments. The 700 series alloys are more brittle compared to the equivalent traditional Stellite alloys.

Available Product Forms:

- Stellite 700 series alloys are available as powder metallurgy components, welding rod, wire and powder.

- Stellite 706, 712 and 703 are available as castings.

- Stellite 720 is available as an UltraFlex coating and additively manufactured components.