Nominal Composition (Mass %) and Physical Properties

| Ni | Cr | Mo | C | Others | Hardness | Density | Melting Range |

| Base | 23 | 18 | .05 | W, Si, Fe | 30 HRC max | 8.6 g/cm3 0.311 lb/in3 | 1280-1360ºC 2336-2480ºF |

| Ni | Cr | Mo | C | Others | Hardness | Density | Melting Range |

| Base | 23 | 18 | .05 | W, Si, Fe | 30 HRC max | 8.6 g/cm3 0.311 lb/in3 | 1280-1360ºC 2336-2480ºF |

Nistelle nickel-baed alloys are designed primarily for high corrosion resistance. They have excellent high-temperature strength, resistance to oxidizing and/or reducing acids (depending on the grade) and are readily machinable.

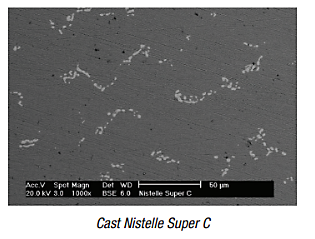

Nistelle Super C is a proprietary welding and thermal spray alloy that exhibits much higher resistance to oxidizing and reducing acids than Nistelle C, and offers significantly higher resistance to chloride-induced, localized attack. Nistelle Super C is also castable. Unlike Nistelle C, which has a chemical composition similar to the wrought version of the alloy, Nistelle SUPER C is specifically formulated as a powder product. It is especially useful as a corrosion-resistant HVOF coating or PTA deposit. It can be used as a corrosion-resistant thermal spray bond coat. Compared to Nistelle C, HVOF coatings of Nistelle Super C are easier to grind to a smooth finish due to the alloy’s lower tendency to work harden.

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?