Premium-Quality HVOF Coating

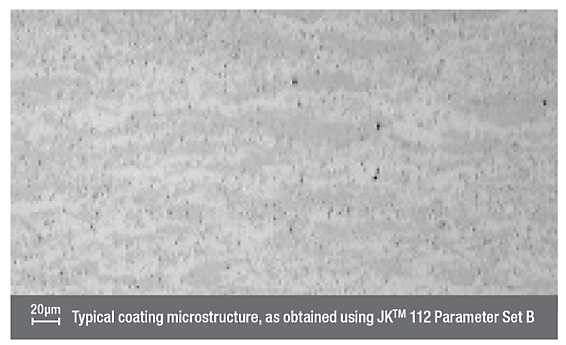

JK 112 powder is manufactured by the agglomeration, sintering, and densification of fine particles of tungsten carbide and cobalt. JK 112 is similar in composition to Praxair D-Gun® LW-1N30 coatings. Highly polished surface finishes are possible because of the fine size and homogeneous distribution of the WC particles.

Typical Applications

JK 112 has excellent resistance to abrasion, low-angle erosion and sliding wear. The extremely high abrasion resistance is associated with lower toughness when compared to JK 117 or JK 120H, both of which contain a higher proportion of metallic binder. JK 112 outperforms hard chrome plating in most wear situations and is often used as a hard chrome substitute. It is especially recommended for applications where a fine coating surface finish is a major requirement. JK 112 is used for the coating of compressor rods, pump casings, pump plungers, pump sleeves, mechanical seal faces, feed screws, gate valves, valve trim, thread guides, paper cutting and slitter knives and fan blades. It is also used for various chemical and petrochemical parts.

Customer Specifications

JK 112 powder and/or coating are similar to BPS 4463, B50TF27 CL.B, F50TF80 CL.B, EMS 57736 Type 2, EMS 52544 Type 2, AMS 7880, RR9507/58, Mil-P-83348 Comp J Type II CL.I, BAC 5851 and ISO 14232 Code 11.12.

Finishing of JK 112 HVOF Coatings

JK 112 coatings are typically finished to 6–14 μ-inches by wet diamond grinding. They can be super finished using diamond-lapping compound to below 1–2 μ-inch (0.025–0.050μm) if required. Coolant must be flooded onto part and wheel during grinding. The coolant may not contain amines, which can attack and pit the cobalt matrix. Spraying and grinding/finishing parameters for JK 112 are available on request.