Nominal Composition (Mass %) and Physical Properties

| Ni | Cr | Fe | Mo | C0 | C | Others | Hardness | Density | Melting Range |

| Base | 22 | 18 | 9 | 1.5 | 0.1 | W, Mn, Si, Nb, Al | 90-98 HRB | 8.22 g/cm3 0.297 lb/in3 | 1260-1355ºC 2300-2470ºF |

| Ni | Cr | Fe | Mo | C0 | C | Others | Hardness | Density | Melting Range |

| Base | 22 | 18 | 9 | 1.5 | 0.1 | W, Mn, Si, Nb, Al | 90-98 HRB | 8.22 g/cm3 0.297 lb/in3 | 1260-1355ºC 2300-2470ºF |

Nistelle nickel-based alloys are designed primarily for high corrosion resistance. They have excellent high-temperature strength, resistance to oxidizing and/or reducing acids (depending on the grade) and are readily machinable.

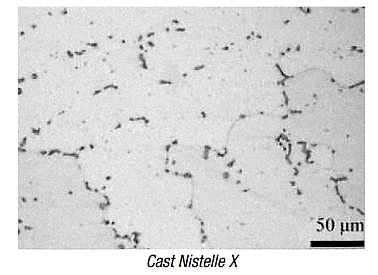

Nistelle X is a nickel-chromium-iron-molybdenum alloy having an exceptional combination of oxidation resistance and high-temperature strength. It has outstanding resistance to stress-corrosion cracking in petrochemical applications. Nistelle X retains good ductility after prolonged exposure to high temperatures.

Nistelle X has been used widely in gas turbines for hot gas path and combustion zone components such as transition ducts, combustor cans, flame holders and afterburners. It is also used in industrial furnace applications due to its resistance to oxidizing, reducing, and neutral atmospheres and in chemical industry processes.

| SPECIFICATION | PRODUCT FORM |

| UNS N06022 | Powder |

| AMS 5390 | Casting |

| ASTM A567 Gr.5 | Casting |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?