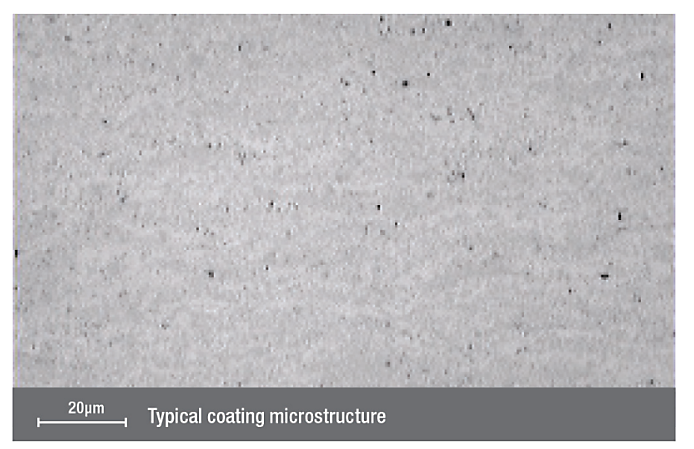

Premium-Quality HVOF Coating

JK 120H is a premium-quality powder developed specifically for the deposition of high-quality HVOF coatings using hydrogen as fuel gas. JK 120P is recommended for carbon-based fuels such as propylene. When deposited using the Jet Kote HVOF system, JK 120H can produce coatings with properties superior to Praxair D-Gun® LW-15. JK 120H coatings can be diamond ground and lapped to smooth surface finishes of <0.025μm (<1 μ-inch) RA.

Typical Applications

JK 120H HVOF coatings replace hard chrome and Praxair D-Gun LW-15 in many industries, including aerospace landing gear and actuators and fuel pump journals. The chromium in the matrix provides excellent corrosion resistance, and JK 120H coatings perform particularly well in wet and dry sour gas (hydrogen sulfide) environments. They are used in a variety of chemical, oil field, and petrochemical applications, for example compressor rod hardfacings, pumps (casings, impellers, plungers, sleeves), mechanical seal faces, feed screws, gate valves and fan blades. Other applications include paper manufacturing suction rolls, brine pumps and centrifugal coal separators.

Superior Abrasion Wear Resitance of JK 120H HVOF Coatings

The volume loss (mm3) of JK 120H vs. JP-5000TM 1350VM and hard chrome in the ASTM G65-91 abrasion test (130N force, 75 rpm) is shown below1. The Jet Kote coating had a significantly lower volume loss than the 1350VM coating, and only one-sixth that of hard chrome. Both coatings were ground to a smooth finish.

Customer Specifcations

Meets AMS 2447B-9 and BMS 10-67 Type XVII.

Finishing of JK 120H HVOF Coating

JK 120H coatings are typically finished to 8–16 μ-inches by wet grinding with diamond media. They can also be super finished to below 1 μ-inch (0.025μm) if required. Spraying and grinding/finishing parameters for JK 120H are available on request.