Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 30.5 | 12.5 | 2.3 | Ni, Fe, Si | 48-63 HRC | 8.69 g/cm3 0.314 lb/in3 | 1250-1290ºC 2280-2355ºF |

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 30.5 | 12.5 | 2.3 | Ni, Fe, Si | 48-63 HRC | 8.69 g/cm3 0.314 lb/in3 | 1250-1290ºC 2280-2355ºF |

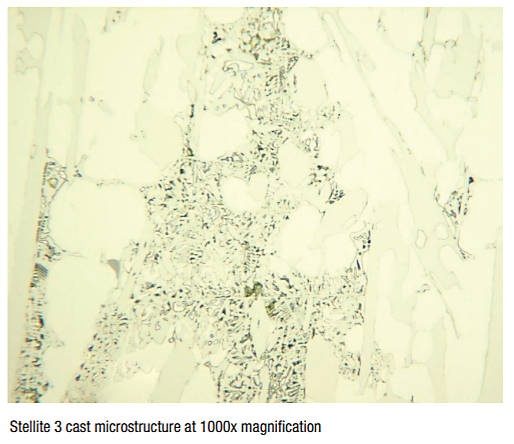

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

The high carbon content of Stellite 3 increases the volume fraction of carbides and hence its abrasion and solid particle erosion resistance. The high tungsten content improves its high-temperature properties. However, this results in an alloy that is nearly impossible to hardface crack-free and one that withstands very little impact. It has excellent metal-to-metal wear resistance and resists galling when mated with other Stellite alloys.

Stellite 3 has been used for valve seat inserts, needle holders, steel mill guide rolls, seaming rolls, sleeves, bushings, bearing balls, wear pads, burner nozzles, palm guides, surgical scissor inserts and in many other applications.

| DESIGNATION | PRODUCT FORM |

| UNS R30001 | Castings |

| UNS R30103 | Powder Metallurgy |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?