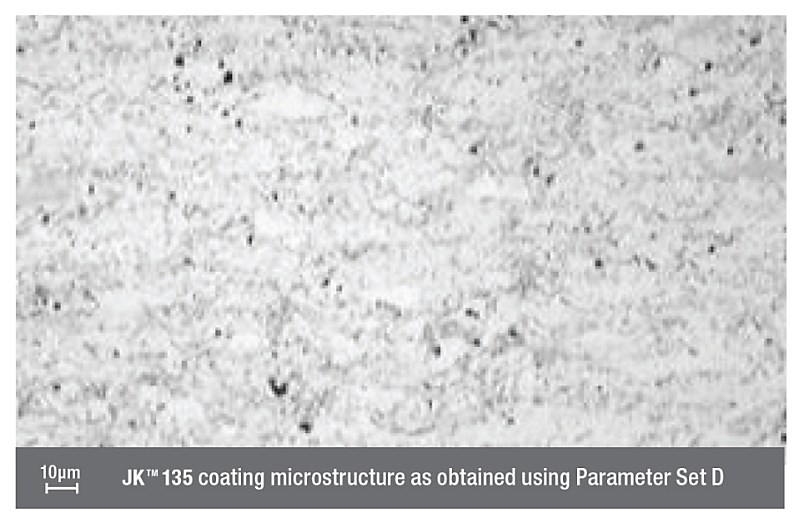

Premium-Quality HVOF Coating

JK 135 is a premium-quality powder developed specifically for the deposition of high-quality HVOF coatings. When deposited using the Jet Kote HVOF system, JK 135 produces coatings with similar, or in many cases superior, performance to Praxair D-Gun® LC-1C and LC-1H, although JK 135 contains less Cr3C2 particles than is typical of these coating compositions. JK 135 coatings can be diamond ground and lapped to smooth surface finishes of <0.05 μm (<2 μ-inch) RA .

Typical Applications

JK 135 HVOF coatings replace hard chrome and Praxair D-Gun LC-1C and LC-1H coatings in many industries. JK 135 is used for the hardfacing of nuclear power plant check and flow control valve seats and seals, and in the aerospace industry on engine stage seal areas, fuel nozzles, compressor and turbine blades for high-temperature oxidation, fretting wear and erosion resistance. Other applications include gas turbine bearing journals, steam valve seats, compressor rods, feed screws, doctor blades, paper drying and calendaring rolls, mechanical seal faces and pump casings, impellers, plungers and sleeves. The NiCr matrix provides excellent corrosion resistance in a wide range of environments. JK 135 coatings perform

well in chemical and petrochemical applications, for example in ball valves, catalytic converter valve stems and guides, heat exchanger components, furnace blowers, fans, thermo-wells and gate valves.

Customer Specifications

JK 135 powder can be certified to B50TF263 Class B. The coating is approved to F50TF77, Class A and B, when sprayed with Parameter Set C or D and the certified powder. The powder meets AMS 2447-3, is approved to Z518 and is similar to AMS 7875, PWA1305, MSRR 9507/17, DMR 33.006, EMS 52432 CL. II and MIL-P-83348-Comp C Type III.

Finishing of JK 135 HVOF Coatings

JK 135 coatings are typically finished to 6–14 μ-inches (0.15- 0.36 μm) by wet grinding with diamond media. They can also be super finished by lapping to <2 μ-inches (0.05 μm).