Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 20 | 15 | 0.1 | Ni, Fe, Si, Mo, Mn | 20-45 HRC* | 8.31 g/cm3 0.300 lb/in3 |

1329-1410ºC 2425-2573ºF |

*Hardness dependent on amount of work hardening.

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 20 | 15 | 0.1 | Ni, Fe, Si, Mo, Mn | 20-45 HRC* | 8.31 g/cm3 0.300 lb/in3 |

1329-1410ºC 2425-2573ºF |

*Hardness dependent on amount of work hardening.

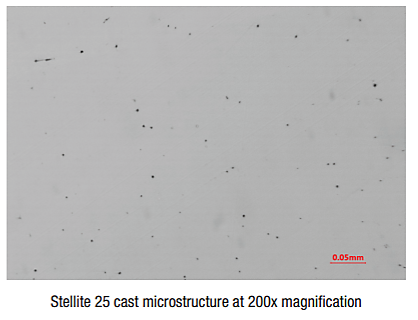

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite 25 is a tungsten-strengthened cobalt-chromium alloy and is the cast version of the wrought alloy L605, and is also available in hardfacing wire, rod, and powder. This special low-carbon alloy has been found to have exceptional thermal fatigue resistance and is useful for tools to work hot steel. The alloy also resists hot metal-on-metal wear.

Stelllite 25 is often used for metal-working tools where a combination of metal-on-metal wear, thermal fatigue, and hot corrosion resistance are required, such as piercing points, forming tools, extrusion dies and furnace hardware.

| DESIGNATION | PRODUCT FORM |

| UNS R30605 | Casting |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

Thank you for your registration, pending approval & completion of the registration, your access is currently limited. Full utilization of product search capabilities & collaboration space is available and will remain. Please allow 2 business days for registration completion.

Thank you for your successful registration. You now have immediate access to log in and utilize the site.

You are about to leave the Solution building process.

Are you sure you want to leave?